Machine that converts excreta into drinking water and electricity

By: Kamakshi Tatkare | Date: 5th November 2019

Image Source: The Climate Center

Image Source: The Climate Center

Bill Gate’s Initiative:

In 2011 Bill Gates launched the Reinvent the Toilet challenge as a part of the Water, Sanitation & Hygiene program to produce and promote new ways for toilet technologies that safely and effectively manage human waste.

The challenge aimed to create toilets which could removes germs from human waste and recovers valuable resources such as energy, clean water, and nutrients.

Later in 2015 Gates drank the water produced from the “Janicki Omni processor” which is a facility that burns human waste and produces water and electricity.

In his notes he says that the major reason for turning waste into drinking water and electricity is that “A shocking number of people, at least 2 billion, use latrines that aren’t properly drained. Others simply defecate out in the open.

The waste contaminates drinking water for millions of people, with horrific consequences: Diseases caused by poor sanitation kill some 700,000 children every year, and they prevent many more from fully developing mentally and physically.”

Janicki Bioenergy:

In order to reinvent the sewage treatment, plant he toured the project which was designed and built by Janicki Bioenergy, an engineering firm based north of Seattle.

It was established in 2014 with waste processing and waste-to-energy as its core focus and ultimately rebranded to Sedron Technologies in 2018.

Insights Into Technical Aspects:

Sedron Technologie’s “Varcor system” is a complete treatment solution which separates the solid and water and then heats, sterilizes, and distills the constituent components.

At the system output, the distilled reuse water is treated to desired quality standards including those sufficient for environmental release, irrigation, reclaimed water, or wastewater treatment discharge.

The solids produced are pathogen-free and are capable of being sold as a commodity. It includes nutrient recovery technology that enables the capture of a concentrated ammonia solution for certain waste streams that can be sold as a fertilizer.

It is based on mechanical vapor recompression which is a evaporation method by which a blower, compressor or jet ejector is used to compress and then increase the pressure of the vapor produced.

Image Source: Sedron

Image Source: Sedron

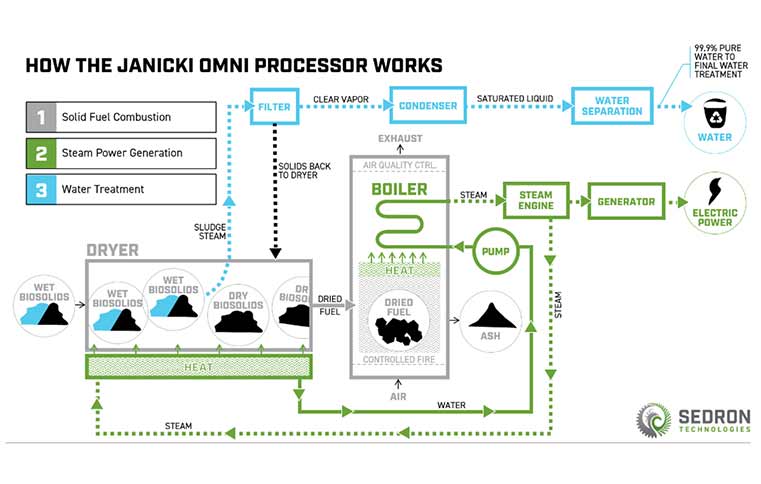

The Process Involved:

The process consists of three major parts:

1. Solid Fuel Combustion

2. Steam Generation

3. Water treatment

Since the fundamental aim of the Janicki Omni Processor is to render fecal sludge pathogen-free in order to stop the spread of disease in an economically sustainable way, the feedstock used consists of wastewater (i.e. digested/undigested sewage sludge, biosolids, residential septage), animal by-products (manure and organic waste), pre-sorted municipal solid waste (MSW), biomass solid wastes, and various industrial waste streams (food and beverage processing waste, distillation by-products, industrial septage).

It requires 10-12 tons of dry waste per day as fuel. At 20% solids, this is 50-60 tons of wet waste per day into the dryer. It is designed to consume the fecal waste or sewage sludge from a population of roughly 100,000 people.

However, as long as adequate dry fuel is supplied from a secondary source (such as garbage, or other solid waste), it can function in a smaller community.

If there is not enough wet sludge to make drinking water, then ground water can be processed in it and brought to potable water standards. It is also possible to scale the technology down if necessary.

Image Source: Sedron

Image Source: Sedron

By Products:

The byproducts include Water and Electricity. When processing 55 wet tons at 20% solids, the J-OP S250 is capable of producing up to approximately 44,000 liters (~11,500 gallons).

It is capable of producing up to 100-200 kW of continuous net power, independent of the electric grid. Also plants can be built that only generate electricity and do not make water.

Impact on Environment:

This ingenious machine eliminates all pathogens, reduces waste volume, reduces odors reduces or eliminates harmful water & soil quality, produces a class A or EQ bio solid for beneficial use or resale, produces a non-hazardous fuel for energy recovery (autogenous operation), eliminate the non-agronomic application of harmful nutrients (P and K).

To read more visit:

How the Janicki Omni Processor works?

This ingenious machine turns feces into drinking water